Building Smart Cities With IoT Technology and Software

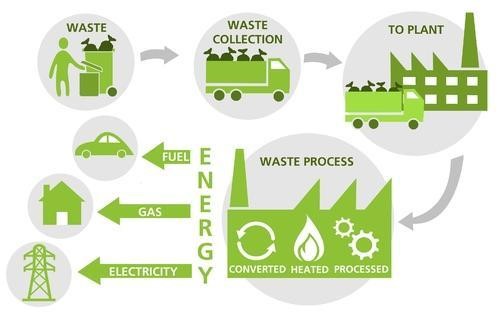

Waste to Energy

Garbage Monitoring

Early warning for Land Slides

W2E ( Waste to Energy )

Market Potential and Economics of Scale

The Asia-Pacific WTE market is projected to grow at an annual rate of over 15 percent and reach a value of US$13.66 billion by 2023

Based on calculations by the World Bank in ‘What A Waste 2.0’ report, India is the largest producer of waste, owing largely to the size of its population. In 30 years, India tipped to double the amount of waste it generates. India is among the Top 5 Municipal Solid waste generators annually. 387.8 Million Tonnes by 2030 and 543.3 Million Tonne by 2050 as projected and has huge electricity need to be fulfilled.

There is an urgent need to implement effective and sustainable waste management solutions including WTE technologies and under circular economy. It can give a fresh life to conventional energy sources. Under Circular economy, Production and consumption design process converts waste to wealth and creates enormous possibilities. It allows the life cycle of products to be extended through a wide range of practices that involve utilisation of waste, raising efficiency and continual use of natural resources. Thus, it is redefining economic growth by placing an increased value on natural and societal capital.

Governments of India are willing to tap into waste-to-energy (WTE) technologies. Waste management has become an imperative given that most cities In India are running out of landfill sites – the traditional method of disposing waste. With increasingly limited land availability and the steady growth of cities.

Public Private Partnerships (PPPs) are a favoured development strategy in the region. Tapping into this market is a variety of commercial banks, multilateral development banks, financial sponsors, and private equity firms

In a typical PPP structure for WTE projects, the developer undertakes the development of the project under the Design-Build-Own-Operate (DBOO) model. In the DBOO model, the developer secures its own financing and builds, owns, maintains and operates the WTE facility to meet the contracted WTE capacity over the lifespan of the facility, which is about 25-30 years.

WTE facilities require significant upfront investments and developers and their financiers require assurances from the government agency commissioning the project that enables the investment to be recovered over time.

Along with government incentives, WTE is based mainly on two sources of revenue. The first source is a gate fee charged when municipalities, businesses or other organizations deliver their waste to the facility for disposal. The second source is the generation of electricity that is sold to local power grids. The more waste that is combustible, like plastics, paper or wood, the hotter the furnaces burn and the higher the caloric value (CV) produced. The more non-combustible waste, like bricks or glass, the lower the CV. This mix determines the facility’s revenue streams. In addition, safety regulations require that the facility is designed for a certain thermal capacity. If the percentage of combustible waste is too high, the CV value will be above the designated level, and the operator will have to reduce the amount of waste going through the facility. This reduces gate fees. However, if the CV is too low, the facility generates less electricity that it can sell.

Balance the right CV and quality of the waste to optimize both waste volumes and electric sales.”

To achieve a viable risk structure for WTE projects, however, initiatives will require close coordination and cooperation among multiple government stakeholders, including the state utility as an off-taker of electricity, municipalities for a supply of waste, and land sites to achieve a bankable PPP structure that ensures stable, predictable cash flow for the WTE plants.

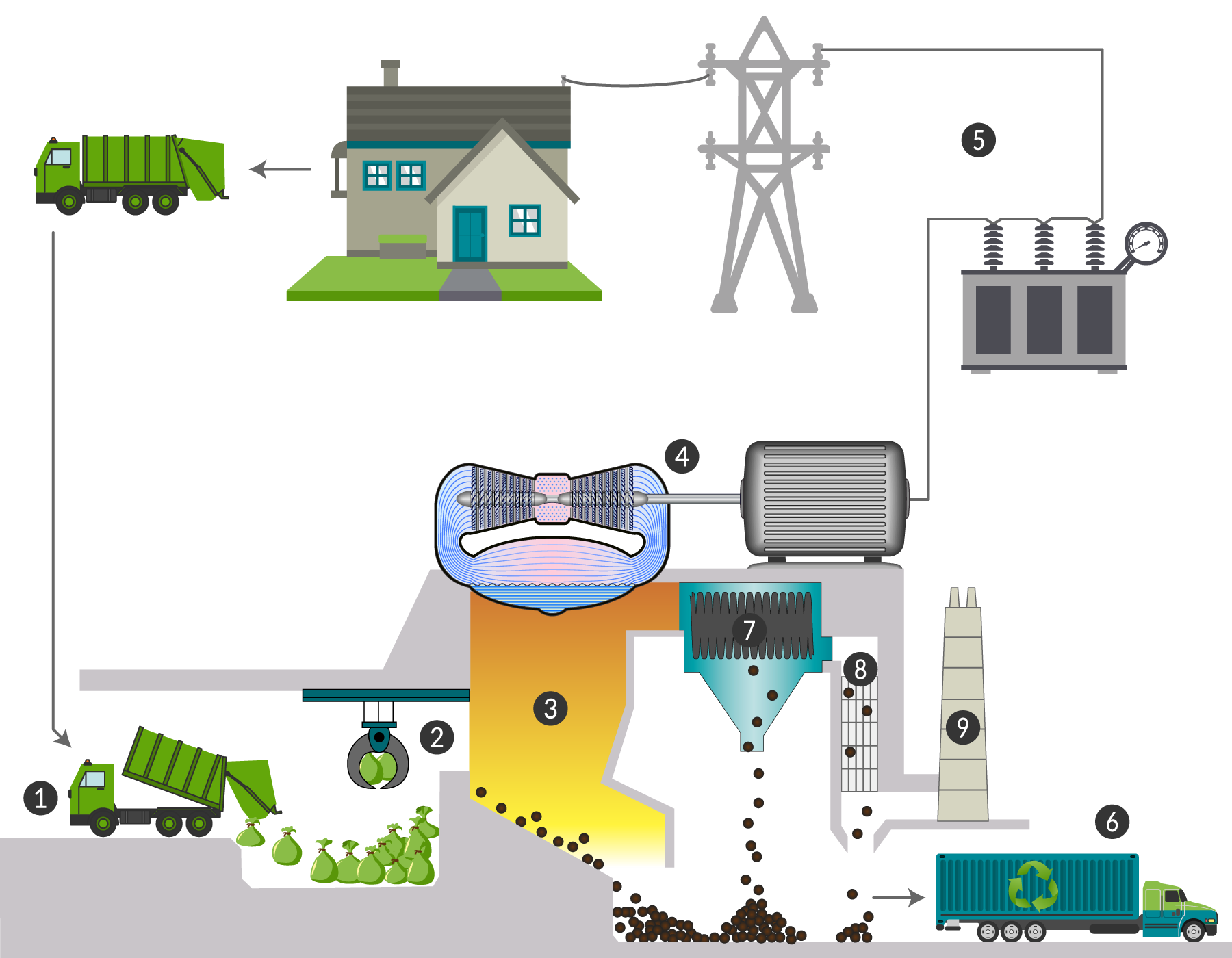

The process of generating electricity in a mass-burn waste-to-energy plant has seven stages:

- Waste is dumped from garbage trucks into a large pit.

- A giant claw on a crane grabs waste and dumps it in a combustion chamber.

- The waste (fuel) is burned, releasing heat.

- The heat turns water into steam in a boiler.

- The high-pressure steam turns the blades of a turbine generator to produce electricity.

- An air pollution control system removes pollutants from the combustion gas before it is released through a smoke stack.

- Ash is collected from the boiler and the air pollution control system.

Consistency and quality of waste is also a key risk factor to lenders and investors. Many emerging economies have limited waste-sorting processes and regulatory requirements to separate different types of waste. Furthermore, Southeast Asian waste can have a significant amount of “wet” waste that includes food waste which is harder to burn, provides a lower caloric value, and can vary in waste type and quality from year to year. For incineration plants, this means a fluctuation in electricity output and revenue uncertainty.

Whether incineration, and waste to energy, is a net positive, can depend on the efficiency of the process, and the energy mix that waste to energy is replacing. The newest incineration plants have far better pollution and dioxin filters to protect the environment and human health. That technology will require governments in emerging markets to make additional investments for products and resources.

There are a number of other new and emerging technologies that are able to produce energy from waste and other fuels without direct combustion. Many of these technologies have the potential to produce more electric power from the same amount of fuel than would be possible by direct combustion. This is mainly due to the separation of corrosive components (ash) from the converted fuel, thereby allowing higher combustion temperatures in e.g. boilers, gas turbines, internal combustion engines, fuel cells. Some are able to efficiently convert the energy into liquid or gaseous fuels:

Thermal treatment technologies:

- Gasification: produces combustible gas, hydrogen, synthetic fuels

- Thermal depolymerization: produces synthetic crude oil, which can be further refined

- Pyrolysis: produces combustible tar/bio oiland chars

- Plasma arc gasificationor plasma gasification process (PGP): produces rich syngas including hydrogen and carbon monoxide usable for fuel cells or generating electricity to drive the plasma arch, usable vitrified silicate and metal ingots, salt and Sulphur.

Non-thermal technologies:

- Anaerobic digestion: Biogas rich in methane

- Fermentation production: examples are ethanol, lactic acid, hydrogen

- Mechanical biological treatment (MBT)

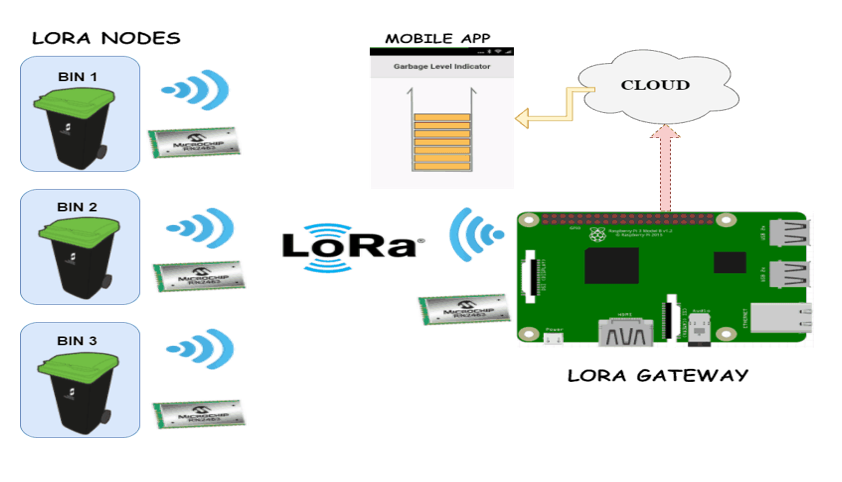

Garbage Monitoring using IoT, LoraWAN and GPS

Business Case

As waste management operations all over the world attempt to become cleaner and greener. We are using the new technologies like GPS Tracking System, Ultra High Frequency Radio Frequency Identification, IOT Sensors along with mobile and web application to improve and smooth ground level mechanisms for waste collection and efficient processing and re-cycling of waste.

The Internet of Things (IoT) shall be able to incorporate transparently and seamlessly a large number of different and heterogeneous end systems, while providing open access to selected subsets of data for the development of a plethora of digital services. Building a general architecture for the IoT is hence a very complex task, mainly because of the extremely large variety of devices, link layer technologies, and services that may be involved in such a system. One of the main concerns with our environment has been solid waste management which in addition to disturbing the balance of the environment also has adverse effects on the health of the society. The detection, monitoring and management of wastes is one of the primary problems of the present era. The traditional way of manually monitoring the wastes in waste bins is a complex, cumbersome process and utilizes more human effort, time and cost which is not compatible with the present day technologies in any way. This an advanced method in which waste management is automated. This project IoT Garbage Monitoring system is a very innovative system which will help to keep the cities clean. This system monitors the garbage bins and informs about the level of garbage collected in the garbage bins via a web page. This web page also send all information to garbage collection vehicles.

Leveraging technologies like LoRa RF, GPS Tracking System, Ultra High Frequency Radio Frequency Identification, IOT Sensors along with mobile and web application to improve and smooth ground level mechanisms for waste collection and efficient processing and re-cycling of waste.

Key Differentiators

- IoT based solution along with integrated command and Control centre

- Long Range. Connects devices up to 10 KM apart in rural areas and penetrates dense urban or deep indoor environments.

- No Tower dependency Wireless Solution. Easy to set up and fast deployment

- Point to Point connection

- Low Power and long battery life for devices

- Geo-location, High Capacity, Low Cost, Chipset

Early warning for Land Slides: Predicting it in advance using IOT

In India, landslide is a major calamity that causes a considerable damage to human life and property. System will predict landslide susceptibility based on various Artificial Intelligence Models. Long Range. Benefits include connects devices up to 10 km apart in rural areas without any wire and penetrates dense urban or deep indoor environments. No Tower dependency, Wireless, easy to set up and fast deployment, Low Power and Long Battery Life for Devices.

From past decades, Landslides remain as one of the most commonly recurring natural tragedies in the Himalayan region, which cause massive loss of lives and property. Worldwide, rainfall is one of the major triggering factors for most of the landslides. This paper provides a detailed topographic and hydro-meteorological study that leads to slope failure and development of IoT and machine learning-based intelligent monitoring systems for early prediction of landslides. The collected data have been utilized to obtain accurate results through the use of back end developed software, and the same has been integrated into the IoT based early warning system to analyze the collected precipitation data in order to monitor and predict the landslides in real-time.

Landslide is one of the repeated geological hazards during rainy season, which causes fatalities, damage to property and economic losses in India. Landslides are responsible for at least 17% of all fatalities from natural hazards worldwide. Due to global climate change, the frequency of landslide occurrence has been increased and subsequently, the losses and damages associated with landslides also have been increased. Therefore, accurate prediction of landslide occurrence, and monitoring and early warning for ground movements are very important tasks to reduce the damages and losses caused by landslides. Various studies on landslide prediction and reduction in landslide damage have been performed and consequently, much of the recent progress has been in these areas. In particular, the application of information and geospatial technologies such as remote sensing and geographic information systems (GIS) has greatly contributed to landslide hazard assessment studies over recent years.